Automation Projects

Our Automation Systems services as Puva; Manufacturing sector: Factory automation systems Construction sector: Building, earthquake automation systems Electricity sector: Smart meter, lighting automation systems Recycling sector: Water treatment, waste paper recycling automation systems Textile sector: fabric dyeing automation systems Energy sector: Energy production, inspection, compensation automation systems Electronics industry: Circuit design, production automation systems Also informatics, telecommunication, office management automation systems

As for the automation programs used in industrial systems, the most preferred programs are; Activex, Speed PLC, Wintr Scad, Data Logger.

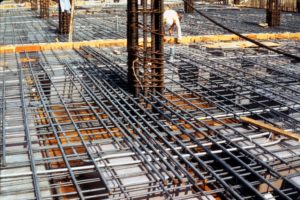

Industrial automation

Automatic production is the basis of modern industry and the general trend of technical progress. This means new fabrication processes, wider application of automation possibilities, the use of automatic processors and industrial robots, various types of loading tools, transfer tables and automatic control systems. For all these, new specialists are constantly required. The current state of industrial production is determined by steadily increasing output, the specialization and integration of production, the standardization of manufacturing processes and factory products, and the demand for uniformity in product parameters. This last requirement is met only as long as the manufacturing conditions practically do not change. The use of new methods in fabrication, assembling and especially metal cutting techniques is the main prerequisite not only for mechanization, but also for automation of manufacturing, tooling and control processes. In industrial automation, mechanics, hydraulics and electronics are combined and force, pressure, speed transmission systems (transducers), relays, amplifiers, signal converters, electrical hydraulic and pneumatic actuators are used as automation tools. In automatic control, cam controls, mechanical stop controls, template controls and numerical controls can be used. In material handling, even simple grooves are considered a part of automation; they also range from separators, feeders, pushers, diverters and robots. Automation is used in measuring processes and setting of benches; automatic turning, milling, drilling and grinding constitute a part of automation. Automation has also entered the assemblies.